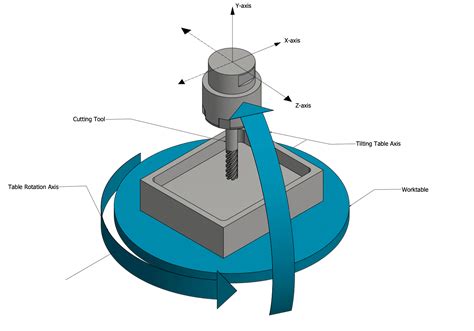

what can a 3 axis cnc machine do A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move .

Distribution Box Types: (1) Distribution Board , It is an open switch cabinet with panel blocking. The front has a protective effect, and the back and side can still touch the live parts.

0 · small 3 axis cnc mill

1 · axis identification in cnc machine

2 · 3 axis vs 5 mill

3 · 3 axis vertical milling machine

4 · 3 axis hobby milling machine

5 · 3 axis cnc milling machine

6 · 3 axis cnc machine price

7 · 2.5 axis milling vs 3

If you are using screws, you will need to purchase the appropriate type of screw for your metal junction box. Make sure that the screw is long enough to go through the box and contact the bare metal inside. If you are .

3-axis CNC milling can machine a wide range of materials, including metals such as steel, aluminum, brass, copper, and titanium, plastics like ABS, polycarbonate, and PTFE, and various types of wood. How does 3 . The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously. Depending on your machining center, you can upgrade to more axes if needed, at an additional cost.3-axis CNC machines are the most common and basic type. They have three linear axes: X-axis: Horizontal movement from left to right. Y-axis: Horizontal movement from front to back.What is 3-Axis CNC Machining? A 3-axis CNC machine is the most basic type of CNC machine, moving the tool or part along three primary axes: X, Y, and Z. This type of machining is .

3-axis machines are ideal for simple tasks that don’t require intricate detailing or depth. As such, it is one of the most preferred techniques for creating mechanical parts for automation. Additionally, you can also use it for cutting sharp edges, . A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move .

The most basic linear axes of a CNC machine tool are the X, Y, and Z axes. CNC machines use computer software to control the movement of cutting tools around a workpiece. Axes are used to describe motion along a .A 3-axis CNC machine is one that performs machining operations by moving its tool or the part along the X, Y, and Z axes. The cutting tool can be moved anywhere along the horizontal (X-Y) plane and cut into parts to specified . We take a closer look at axis machining, and the versatility, availability, and affordability which make a 3-axis CNC the best CNC milling machine.What is 3-Axis CNC Machining? A 3-axis CNC machine is the most basic type of CNC machine, moving the tool or part along three primary axes: X, Y, and Z. This type of machining is commonly used for simple and flat geometries. Understanding Each Axis and How It Works. X-Axis: Moves the tool left and right. Y-Axis: Moves the tool forward and backward.

The 3-axis CNC machine configuration is primarily found in CNC milling machines. In these machines, the workpiece is held in place by a vise. The vise, in turn, is fixed to a moving table. Designed to move, the table travels . 3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and .Ya i wouldn't need those kinda of tolerances and most of the parts i want to make would be pretty small. most objects would be under 4 inches. many under 2. i've seen people use resin instead of machining for cnc routers to get a "flat" surface. whats your thoughts on that if i want like +/- .003 to .004 on axis for 4 inch parts? A 5-axis CNC machine is a sophisticated tool that allows for the creation of complex parts with high precision and flexibility. Its ability to move in five different directions means it can .

4-Axis CNC Machining. A 4-axis CNC machine functions much like its 3-axis counterpart. The workpiece is in a stationary position, and the cutting tool works on it to remove material and mold the desired part. However, as the name indicates, 4-axis machining adds an axis of rotation to the standard X, Y, and Z planar movement.

small 3 axis cnc mill

axis identification in cnc machine

The successful candidate will have experience with 3, 4 and/or 5 axis CNC machine setting and operating. ***** PLEASE EXPLAIN WHAT MACHINES YOU HAVE EXPERIENCE RUNNING, IN EITHER YOUR RESUME AND/OR YOUR COVER LETTER OR .If you don't know why you need 5 axis then don't buy 5 axis. Edit: You can knee jerk downvote this, but fixturing and programming 5-axis work is an order of magnitude more complex than 3 axis work and the costs in work envelope reduction .

The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously. Depending on your machining center, you can upgrade to more axes if needed, at an additional cost. If you’re not sure how many axes or how complex your piece is, .

Precision and Surface Finish: The accuracy of 5-axis CNC machines is better than that of 3-axis CNC machines, thanks to the various perspectives from which the workpiece can be approached. This lessens the need to reposition the workpiece after most cutting tasks or realign the machine, which can create errors in 3-axis machining. The X-axis moves left to right, the Y-axis moves from front to back, and the Z-axis moves up and down. A 3 axis CNC machine can work on each axis at the same time. These CNC machines are mostly used for cutting flat 2D and 2.5D parts. It is possible to machine all six sides of a part with a 3 axis CNC machine, but it requires a new fixturing .Figure 1 is an example of a 3-axis CNC machine: What Can a 3-Axis CNC Do? A typical 3-axis CNC machine is capable of carrying out a variety of machining tasks, including: cutting, drilling, and milling. Others are designed as CNC lathes. However, in terms of part complexity, the constraint of those three axes means the machine has some distinct .

What is CNC Machining?CNC stands for computer numerical control. So, CNC machining is any kind of machining process controlled by a computer. Computerized au.The 3-axis CNC milling machine is a versatile, multi-purpose machine that can be used to mill complex shapes. Unlike conventional milling machines, 3-axis CNC machines are capable of performing all three axes of movement. The first step to program a CNC machine for 5-axis milling is to choose the right machine and software for your project. Different machines have different configurations and capabilities, such as .

Going to do a 3 axis cnc conversion. Might even investigate feasibility of a VFD for the spindle. Posted: 3/14/2014 12:21:18 PM EST [#21] Quote History. Quoted: I have a . Even buying a machine to do it, if you have . Visualize a box; the length, breadth, and height of this box correspond to the X, Y, and Z axes, respectively. A 3-axis CNC milling machine can move its tool along any of these dimensions singularly or even combine .A 3-axis CNC machine has three linear axes: X, Y, and Z, allowing it to move the tool or the workpiece in three directions. This type of machine is the most common and basic, and can be used for .

The choice between 3-axis and 5-axis CNC machining largely depends on the specific needs of your project. If you're working on simple parts with less complexity and a tighter budget, 3-axis machining may be the way to go. However, for projects that demand high precision and complex geometries, investing in a 5-axis machine can significantly . What can a 3-axis CNC do? A typical 3-axis CNC machine can perform a variety of machining tasks, including cutting, drilling, and milling. Others are designed as CNC lathes. However, when it comes to part complexity, the limitation of these three axes means the machine has some distinct limitations. The best 3-axis machines are used to produce .The rest of the time is more complex 3D geometry for things like large vacuum form/carbon fiber moulds, some times I can get away with using a ball nose tool and 3 axis programming to do "steps down" but if i need a really high quality finish then the tool head really needs to rotate to follow the flow of the surface so just more manual data .Overall, the 3 axis machine would take 5 hours and 15 minutes to manufacture a single component. 5 axis CNC – operations described. It’s all so much easier with a 5 axis machine! Just two operations as follows: combines 3 axis operations 1 – 3 and 5 – 7: Partial profiling to allow handling of excess stock. Set in vice, set datum.

Fusion360 does simultaneous 5 axis toolpaths, it just doesn't do surfacing very well yet. Fusion 360 does 3+2. Fusion 360 does NOT do 5 axis continuous machining. There's a substantial difference between using all 5 axis in a toolpath (3+2 indexing), and being able to move 4 or 5 axis simultaniously while milling.

People who have experience on cnc router and machinery know that cnc machine have 3 axis , 4 axis and 5 axis . 90% people know well the 3 axis and 4 axis cnc router but only little part of people are familiar with the 5 axis cnc machine. Do you want a detailed understanding of 5 axis cnc machine Application and what can a 5 axis cnc machine make? How small are you looking for? I can sell you a Defiance CNC mill for 5k and all you have to do is get power and air to it. A good machine for small parts, low production, prototyping. 40,000 RPM spindle. I also have a Tree Journeyman 325. Dynapath Delta 20 control. This machine is about the size of a Bridgeport but weighs about 2x. 4500.00 . e.g. 3+1 would typically mean simultaneous 3-axis movement with the 4th axis (probably an A axis in most cases) being used only as a positioner. 3+2 would mean the same except that it could be an A and C (or B and C) being used as a positioner. A CNC machine tool is a machine that is computer-controlled. It has machine tools like the spindle, the tool table, and others. CNC machine tools can create 2D shapes or 3D shapes using a control program which is loaded onto the computer attached to the machine tool. This article will discuss the 3 axis CNC

3 axis vs 5 mill

electrical outlet box rough in

There are many combinations of Steel Plate and Sheet types and finishes. From types such as A36 or 516-70 to finishes from hot rolled to cold rolled.

what can a 3 axis cnc machine do|2.5 axis milling vs 3